In today’s fast-paced world, the demand for clean and safe drinking water is higher than ever. With the rise in bottled water consumption, businesses and manufacturers are turning to advanced water packing machines to streamline production and meet market needs efficiently. These machines play a crucial role in ensuring hygienic, high-speed, and cost-effective packaging for bottled and pouch water.

What is a Water Packing Machine?

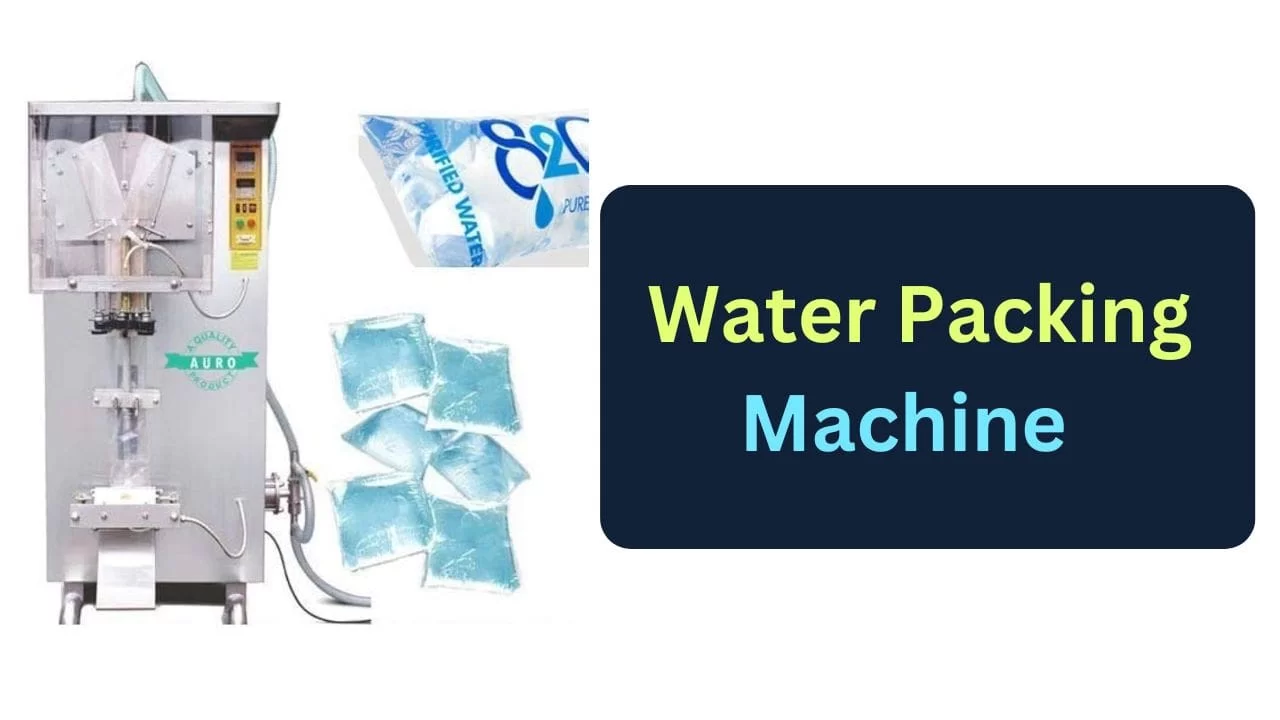

A water packing machine is an automated or semi-automated system used for filling, sealing, and packaging water in bottles, pouches, or cans. These machines cater to industries such as mineral water plants, beverage companies, and small-scale water packaging businesses.

Types of Water Packing Machines

There are different types of water packaging machines based on their working mechanism and packaging style. Some of the most common types include:

1. Automatic Water Bottling Machine

- Used for packaging water in plastic or glass bottles

- Includes filling, capping, and labeling units

- High-speed operation, ideal for large-scale production

2. Pouch Water Packing Machine

- Designed for filling and sealing pouches with drinking water

- Mostly used for small water suppliers and low-cost water packaging

- Compact and energy-efficient

3. Cup Water Filling Machine

- Specialized for packaging water in small cups with airtight sealing

- Popular in airline catering, events, and hotels

4. Sachet Water Packing Machine

- Produces single-use sachets for easy and portable drinking water

- Cost-effective and widely used in developing markets

How Water Packing Machines Work

The functionality of a water packing machine varies based on the type, but the general working principle includes:

- Water Purification – The machine first ensures the water meets health and safety standards.

- Filling Process – Water is filled into bottles, pouches, or cups through an automated nozzle system.

- Sealing & Capping – The filled containers are sealed or capped securely to prevent leakage or contamination.

- Labeling & Coding – The packaged water is labeled with brand details and date codes.

- Final Inspection & Packing – The finished products undergo quality control before being packed into cartons for distribution.

Benefits of Using a Water Packing Machine

1. Increased Production Efficiency

Automatic machines can fill and pack thousands of bottles per hour, significantly boosting production capacity compared to manual labor.

2. Hygienic and Safe Packaging

These machines use food-grade materials and airtight sealing techniques to maintain the purity of drinking water, preventing contamination.

3. Cost-Effective in the Long Run

Though the initial investment may be high, a water packing machine reduces operational costs, labor expenses, and wastage in the long term.

4. Customization & Scalability

Businesses can choose machines with customizable filling capacities and packaging options to suit their specific needs and growth.

Top Water Packing Machines in 2025

For those planning to invest in a water packing machine, here are some of the top-rated models available in 2025:

1. Aquatech Pro Fill 5000

- Type: Automatic Water Bottling Machine

- Capacity: 5000 bottles/hour

- Price: $12,000

- Features: Multi-stage purification, high-speed filling, durable stainless steel body

2. PurePack 3000 Pouch Packing Machine

- Type: Pouch Water Packing Machine

- Capacity: 3000 pouches/hour

- Price: $8,500

- Features: Digital control panel, energy-efficient, easy maintenance

3. Hydropack Smart Cup Filler

- Type: Cup Water Packing Machine

- Capacity: 2000 cups/hour

- Price: $6,500

- Features: High precision sealing, leak-proof packaging, user-friendly design

4. AquaSachet 2000

- Type: Sachet Water Packing Machine

- Capacity: 2000 sachets/hour

- Price: $5,000

- Features: Compact size, automatic cutting & sealing, cost-effective

Factors to Consider Before Buying a Water Packing Machine

If you’re planning to invest in a water packing machine, keep the following factors in mind:

1. Production Capacity

Choose a machine that aligns with your business’s daily production goals. High-speed machines are essential for large-scale operations, while small-scale businesses can opt for mid-range machines.

2. Machine Durability & Material

Look for machines made from stainless steel or food-grade materials to ensure longevity and hygiene compliance.

3. Energy Consumption

Machines with energy-efficient technology help reduce electricity costs and promote sustainable operations.

4. Automation Level

Fully automatic machines offer better efficiency and speed, whereas semi-automatic machines may require manual assistance.

5. Maintenance & Spare Parts Availability

Check if the machine has easily replaceable parts and if servicing support is available in your region.

How to Start a Water Packaging Business in 2025

The demand for packaged drinking water is growing due to urbanization and health-conscious consumers. Here’s how you can start your own water packaging business:

Step 1: Register Your Business

Obtain the necessary licenses and health certifications required for food and beverage businesses in your country.

Step 2: Set Up a Water Purification Unit

Install an RO (Reverse Osmosis) system or UV filtration to ensure clean and safe drinking water.

Step 3: Purchase a Water Packing Machine

Choose the right machine based on your budget and production goals.

Step 4: Design Packaging & Branding

Create an attractive label with all required details such as manufacturing date, expiry date, and water source.

Step 5: Market & Distribute

Reach out to retailers, supermarkets, and online platforms to sell your packaged water.

Conclusion

The water packing machine industry is evolving with new innovations that enhance efficiency, sustainability, and affordability. Whether you’re a startup or an established beverage manufacturer, investing in a high-quality water packing machine can help you scale your business while maintaining top-notch quality and hygiene.

By understanding the different types, benefits, and factors to consider before purchasing, you can make an informed decision and thrive in the booming packaged water industry in 2025.